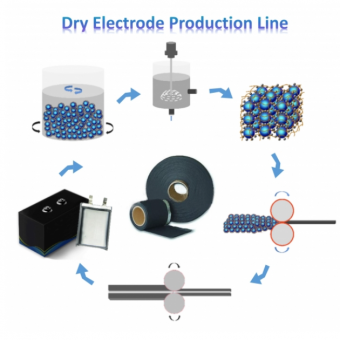

Heating Rolling Laminating Machine for Dry Electrode Production

Ⅰ、Introduction

The dry electrode process is a new manufacturing process for lithium-ion batteries, which does not use solvents in the electrode manufacturing process. Usually, the positive/negative active substances, conductive agents, and solid binders are directly mixed and sprayed onto the collector, or a self-supporting film is made through different processes and then compounded with the collector. This process does not use a large amount of organic solvents, which is beneficial for extending the capacity and cycle life of the battery.

Ⅱ、Main machine composition

Heating and rolling laminating production line consists of 3 equipments:

1)Horizontal heating roller press machine ,

2)Vertical heating roller press machine,

3) Laminating heating roller press machine.

.The main machine is equipped with a heating control system, a roller gap adjustment mechanism, and corresponding feeding devices, pre heating devices, edge cutting devices, winding devices, adhesive coating devices, laminating devices, and tension detection devices The drive and tension control system, as well as the disassembly and assembly roller device, complete processes such as powder preheating, feeding, heating roller rolling, edge cutting, secondary hot roller pressing, gluing, lamination, and winding.

Horizontal Heating Roller Press Machine

Model: TMAX-ZY300-H400-W

Structural form: Horizontal arrangement of heating rollers, with integrated design of feeding, pre heating, edge cutting, and winding

Roll size: φ 300 * 400mm;

Roll surface roughness: Ra ≤ 0.04 μ M;

Roll radial runout: ≤ 0.002mm

Heating method: Solid roller drilling and hole arrangement are matched with an external mold temperature machine, which is heated through thermal oil circulation; Heating temperature: Max.150 ± 2 ℃

Roll gap adjustment range: 0-15mm; Roll gap adjustment form: servo motor drives reducer and screw mechanism to accurately control roll gap spacing

Pressure adjustment range: 0-75t, maximum line pressure 2.5t/cm, adjustable online

Main motor power: 5kW (380V 50HZ servo motor);

Roller pressing speed: 0.5-9m/min (stepless speed regulation)

Equipment dimensions: approximately L3.8m × W2.1m × H2.1m

Vertical Heating Roller Press Machine

Model: TMAX-ZY300-H400-L

Structure: vertically arranged heating rollers up and down;

Integrated design of unwinding, trimming, and rewinding

Roll size: φ 300 * 400mm;

Roll surface roughness: Ra ≤ 0.04 μ M;

Roll radial runout: ≤ 0.002mm

Heating method: Solid roller drilling and hole arrangement are matched with an external mold temperature machine, which is heated through thermal oil circulation;

Heating temperature: Max.150 ± 2 ℃

Roll gap adjustment range: 0-2mm, roll gap adjustment form:

The servo motor drives the wedge iron adjustment through a reducer and ball screw

Pressure application method: The dual constant pressure hydraulic station applies pressure through a plunger cylinder. The maximum pressure between the two rollers is 150t, and the maximum line pressure is 5t/cm

Main motor power: 5kW (380V 50HZ servo motor); Roller pressing speed: 0.5-9m/min (stepless speed regulation)

Equipment dimensions: approximately L2.3m × W2.1m × H1.9m

Laminating Heating Roller Press Machine

Structure: Vertical heating rollers arranged up and down, dual station unwinding, gluing, drying, laminating, and winding devices designed in one piece

Roll size: φ 300 * 400mm;

Roll surface roughness: Ra ≤ 0.04 μ M;

Roll radial runout: ≤ 0.002mm

Heating method: Solid roller drilling and hole arrangement are matched with an external mold temperature machine, which is heated through thermal oil circulation;

Heating temperature: Max.150 ± 2 ℃

Roll gap adjustment range: 0-2mm, roll gap adjustment form: servo motor drives wedge iron adjustment through reducer and ball screw

Pressure application method: The dual constant pressure hydraulic station applies pressure through a plunger cylinder. The maximum pressure between the two rollers is 150t, and the maximum line pressure is 5t/cm

Main motor power: 7kW (380V 50HZ servo motor), roller pressing speed: 0.5-15m/min (stepless speed regulation)

Overall dimensions of the host: approximately L3.3m × W2.1m × H1.9m

en

en fr

fr de

de ru

ru es

es pt

pt ko

ko tr

tr pl

pl th

th

IPv6 network supported

IPv6 network supported